ACHIEVE SUSTAINABILITY

Provide you with the highest-quality products and services possible in a timely fashion and at a competitive price.

Bonusser og kampagner hos Trickz

Trickz tilbyder et bredt udvalg af bonusser og kampagner designet til danske spillere. Velkomstpakken indeholder tre trin med i alt 300 gratis spins, kombineret med særlige reload-tilbud i løbet af ugen. Spillere kan også forvente cashback-tilbud, mystery-bokse og weekend-boosts. Vigtigst er det at forstå omsætningskravene og begrænsningerne for maksindsatser og ekskluderede spil, før du accepterer en belønning. For at se aktuelle vilkår og nyeste kampagner kan du besøge Trickz casino online i Danmark og finde detaljer om krav til minimumsindskud, omsætningsmultiplikatorer og spilbegrænsninger.

| Tilbud | Type | Hovedkrav |

|---|---|---|

| Første indskud – 100 gratis spins | Velkomst | Min. indskud €20 – 25x omsætning |

| Andet indskud – 200 gratis spins | Velkomst | Min. indskud €20 – 25x omsætning |

| Weekly Cashback | Cashback | Deposit for at låse op – 25x omsætning |

Trickz sætter klare begrænsninger på maksindsatser ved brug af bonusmidler – typisk €2 for første og andet indskud og €5 for tredje. Enkelte spiltyper som live casino, roulette, blackjack, baccarat og progressive jackpots er ofte ekskluderet fra spillekravene, så tjek altid den specifikke kampagnebeskrivelse. Også gebyrer og udbetalingsregler påvirker dit afkast – der kan være faste gebyrer på indskud og udbetalinger, samt en mindsteudbetalingsgrænse som du skal kende.

- Læs omsætningsbetingelserne grundigt før accept

- Tjek hvilke spil der bidrager til omsætning

- Hold øje med maksindsats ved bonusspil

- Vær opmærksom på minimumsindskud på €20

- Benyt cashback-tilbud strategisk efter tab

- Kontakt support ved uklarheder omkring bonusregler

For danske spillere er det også essentielt at bruge ansvarlige spilleværktøjer og at kende vilkår for kontoaktivitet – eksempelvis gebyrer for inaktivitet og krav til identitetsverifikation før udbetaling. Trickz tilbyder værktøjer som tabsgrænser, cool-off perioder og selvudelukkelse – disse kan hjælpe med at kontrollere aktivitet under kampagner. Hvis du har spørgsmål til specifikke kampagner eller krav, står support ofte til rådighed døgnet rundt på engelsk, og information om verifikation og KYC findes i betingelserne.

Bonuser og kampagner hos Trickz

Trickz tilbyder en række attraktive bonustilbud og kampagner designet til danske spillere, fra velkomstpakker til ugentlige belønninger og VIP-fordele. På startsiden fremhæves en velkomstpakke med op til 300 gratis spins fordelt over de første indbetalinger og flere løbende tilbud som Tuesday Mystery Box, Weekend Recharge og Weekly Cashback. For en hurtig adgang til platformens kampagneside kan du besøke spil slots og live casino hos Trickz hvor du får et overblik over aktuelle tilbud og krav. Husk at de fleste bonusser kræver mindst €20 i indbetaling og har et omsætningskrav på 25x deposit+bonus samt maksimale indsatser på €2 eller €5 afhængig af kampagnen.

| Kampagne | Hoveddetaljer | Krav |

|---|---|---|

| Velkomstpakke | Op til 300 gratis spins over tre indbetalinger | Min indbetaling €20 – omsætning 25x |

| Weekly Cashback | Ugentlig cashback for kvalificerede spillere | Min indbetaling €20 – omsætning 25x |

| Tuesday Mystery Box | Mystery-bonusser på udvalgte spil hver uge | Min indbetaling €20 – omsætning 25x |

Det er vigtigt at være opmærksom på begrænsninger og undtagelser – når du spiller med bonusmidler, gælder ofte spilrestriktioner som udelukkelse af roulette, blackjack, baccarat, live-spil og progressive slots fra bonusspil. Maksimale indsatser med aktive bonusser er angivet i vilkårene for den enkelte kampagne – typisk €2 for første og anden indbetaling og €5 for tredje indbetaling. Derudover kan Trickz håndhæve en turnover-grænse før udbetaling og opkræve en 10% gebyr ved tidlig udbetaling uden opfyldt turnover – så læs altid betingelserne før aktivering.

- Tjek altid minimumsindbetaling og omsætningskrav før du accepterer en bonus.

- Undgå at overskride maksindsatsen når en bonus er aktiv for at undgå bonusmisbrug.

- Vælg spil der bidrager mest til omsætningen hvis du vil frigøre bonusmidler hurtigere.

- Hold øje med tidsbegrænsninger og udløbsdatoer for gratis spins og cashback.

- Udnyt ugentlige kampagner som Weekend Recharge og Tuesday Mystery Box for ekstra værdi.

Trickz gør meget ud af at kombinere velkomsterbjudanden med tilbagevendende belønninger og en Loyalty Program for hyppige spillere, men vilkårene kan variere og administration af kampagner sker under operatørens regler. For danske spillere er det også værd at bemærke gebyrer og krav omkring ind- og udbetalinger, samt at ansvarligt spil anbefales – læs vilkårene og spil ansvarligt når du benytter kampagner og bonustilbud hos Trickz.

Bonuser og kampagner hos Trickz

Trickz tilbyder et bredt udvalg af bonustilbud og kampagner designet til at give nye og loyale spillere ekstra værdi. Velkomstpakken på Trickz indeholder typisk flere stadier med gratisspins og reload-tilbud, men det er vigtigt at forstå omsætningskrav og maksindsatsbegrænsninger før du accepterer en bonus. Mange spillere søger information om hvordan man får mest ud af kampagnerne, hvilke spil der tæller med til omsætningen, og hvilke spil der er udelukket. Hvis du vil have et hurtigt overblik og starte direkte, kan du besøke vores side for at spil slots hos Trickz online og se aktuelle tilbud og betingelser.

| Kampagne | Hvad den giver | Nøglebetingelser |

|---|---|---|

| Velkomstpakke | 300 Free Spins fordelt på 3 indskud | Min indskud €20 – 25x omsætning – Max indsats €2 for første og anden |

| Tuesday Mystery Box | Ugentlige mystery bonusser | Min indskud €20 – 25x omsætning – Ekskluderede live spil |

| Weekend Recharge | Reload bonusser hver weekend | Min indskud €20 – 25x omsætning – Max indsats kan variere |

Når du vurderer en kampagne hos Trickz er det vigtigt at kende til omsætningskravet på 25x for bonusser baseret på indskud plus bonus. Der er også forudgående omsætningskrav før udbetaling ved visse situationer – for slots er grænsen typisk x3 på indskud, mens andre spil kan kræve x5. Spillere bør bemærke maksindsatser under aktive bonusser – normalt €2 for første og anden indbetaling og €5 for tredje indbetaling – og at roulette, blackjack, baccarat, live casino og progressive jackpots ofte er udelukket fra bonusspillet. Desuden kan tidlige udbetalinger før opfyldt omsætning medføre en gebyrprocent på 10 percent af udbetalingsbeløbet. Husk også de faste gebyrer – depositum kan have et fast gebyr €1 og udbetalinger har et fast gebyr €2.

- Læs altid vilkår før du accepterer en bonus

- Kontroller hvilke spil der bidrager til omsætning

- Sæt et personligt tabstak for sikker spiloplevelse

- Udnyt reload-tilbud på lave indsatsniveauer

- Hold øje med maksindsats regler ved bonus

- Kontakt support ved spørgsmål om betingelser

Trickz kombinerer store velkomstpakker med løbende ugentlige kampagner for at holde spiloplevelsen frisk. For danske spillere er det særligt vigtigt at tjekke mindsteindskud, omsætningskrav og eventuelle administrative gebyrer ved inaktivitet. Spil ansvarligt, brug værktøjer til grænser hvis nødvendigt, og husk at kontakte Trickz support hvis noget er uklart – support er tilgængelig døgnet rundt for hjælp.

Bonustilbud og kampagner hos Rabbitreel i Danmark

Rabbitreel tilbyder et bredt udvalg af bonustilbud og kampagner, skræddersyet til spillere i Danmark. Velkomstpakken er særlig generøs og fordelt over de første seks indskud med en kombination af matchbonusser og free spins. For danske spillere betyder det typisk et minimumsindskud på 20 EUR, omsætningskrav på 25x deposit+bonus og en maksimal gevinstbegrænsning på free spins. Udover velkomsten findes ugentlig cashback og løbende reload-tilbud, samt særlige tidsbegrænsede kampagner. Læs mere om tilbuddene hos Rabbitreel online casino og få detaljer om omsætningskrav, gyldighedsperioder og begrænsninger.

| Kampagne | Beskrivelse | Vilkår |

|---|---|---|

| Velkomstpakke | Op til 1.650 EUR + 1.277 free spins | 25x deposit+bonus, min 20 EUR |

| Ugentlig Cashback | Op til 15% tilbage på slots | 1x omsætning, max 5.000 EUR |

| Reload-tilbud | Regelmæssige genindskudsbonuser | Vilkår varierer se kampagnebetingelser |

Velkomstpakken hos Rabbitreel kan være fordelagtig for spillere, men husk at omsætningskravet på 25x deposit+bonus betyder, at både indskud og bonus skal omsættes før udbetaling. Maksimal indsats ved aktiv bonus er 5 EUR pr. spin eller tilsvarende i anden valuta, og free spins er normalt gyldige i 7 dage med et maksimumsudbetalingstak på 5.000 EUR fra free spin-gevinster. Ugentlig slots cashback giver op til 15% tilbage på nettotab i den specificerede periode, men cashback har et 1x omsætningskrav og begrænses ofte til udvalgte spil under Bonus Games. Husk også minimumsindskuddet på 20 EUR for at kvalificere dig til velkomsttilbuddet og at visse kampagner kan være eksklusive for bestemte lande. Vær opmærksom på, at visse stage-tilbud kan have kortere gyldighedsperioder, typisk 48 timer til komplet omsætning, og at gratis spins ofte er bundet til specifikke spilleautomater som Big Bass Splash eller Rise of Olympus Extreme. Forstå også gevinstbegrænsninger fra free spins og konverteringslofter for bonusser – disse detaljer står i de enkelte kampagnebetingelser.

- Indskud min 20 EUR for at aktivere velkomstpakken

- Omsætningskrav er 25x deposit+bonus for de fleste velkomstbonuser

- Free spins udløber normalt efter 7 dage og har maksudbetaling

- Cashback udbetales ugentligt – 1x omsætning og max 5000 EUR

- Betalingsmetoder som Visa, Mastercard, Apple Pay og Instant Banking

- Kontakt support for kampagnespørgsmål via live chat eller e-mail

Det er afgørende at læse de enkelte kampagnevilkår grundigt hos Rabbitreel før du accepterer et tilbud – især fordi begrænsningerne for bidrag fra live casino og bordspil ofte er 0% til omsætningen. Brug ansvarlige spilleværktøjer som depositgrænser, sessionstimer og selvudelukkelse hvis du oplever kontrolproblemer. Kontakt kundesupport via live chat eller e-mail for spørgsmål om kvalifikation og udbetalinger. For danske spillere anbefales det altid at tjekke lokale regler for online spil og sørge for at spillere er over 18 år.

Mobilspil og app-funktioner hos Rabbitreel

Rabbitreel fokuserer på mobilspillere i Danmark med en responsiv platform, der er optimeret til både iOS og Android-enheder. I stedet for en tung native app tilbyder site et hurtigt og let brugerinterface, som tilpasser layout og kontrolflader automatisk til mindre skærme. Registreringen er kort og mobilvenlig – telefonnummer, SMS-kode og en personlig PIN sikrer hurtig adgang. Indbetalinger er øjeblikkelige og understøtter populære metoder som Apple Pay og Instant Banking, hvilket gør det nemt at spille på farten. Vil du læse mere eller besøge siden direkte, kan du bruge dette link til det officielle site: Rabbitreel online casino for hurtig adgang.

| Funktion | Beskrivelse |

|---|---|

| Responsiv design | Tilpasser layout til mobil og tablet. |

| Native app | Ingen native app ved lancering – responsiv webapp i stedet. |

| Betalingsmetoder | Apple Pay, Instant Banking og kort. |

| Sikkerhed | Kryptering, KYC og MGA-licens. |

Mobiloplevelsen hos Rabbitreel prioriterer hastighed og stabilitet – især for spillere i Danmark, der forventer hurtige indbetalinger og simple navigationer. Siden er bygget som en responsiv webapp, hvilket betyder at der ikke nødvendigvis er en separat app at installere, men at funktionerne er let tilgængelige via browseren. Spil starter hurtigt, grafik og lyd tilpasses automatisk, og casinolobbyen tilbyder filtrering efter leverandør og type, så du nemt finder favoritspil. KYC-processen er også mobiloptimeret – upload af ID og adressebevis foregår direkte fra telefonen. Tilbagebetalinger og udbetalinger håndteres effektivt, ofte inden for få minutter ved brug af e-wallets eller Instant Banking efter verifikation.

- Brug portrait mode for bedre kontrol over spin- og sats-knapper og for at undgå uønsket zoom.

- Tjek netværksindstillinger – stabil WiFi eller mobildata sikrer færre afbrydelser og hurtigere loadtid.

- Aktivér push-notifikationer kun hvis du vil have bonustilbud og cashback-opdateringer.

- Sæt indbetalings- og sessiongrænser i profilens Sensible Play Settings for ansvarligt spil.

- Gem ofte brugte betalingsmetoder i din konto for at fremskynde indskud på mobilen.

- Brug live chat direkte fra mobilen ved spørgsmål om KYC eller hurtige udbetalinger.

Som dansk spiller er det vigtigt at bemærke at Rabbitreel opererer under en Malta-licens og følger EU-regler for databeskyttelse og ansvarligt spil. Mobiloplevelsen kombinerer hurtige betalingsløsninger med indbyggede værktøjer som depositgrænser, sessionbegrænsninger og reality check-popups for at hjælpe dig spille ansvarligt. Support er primært på engelsk via 24/7 live chat og email hvis du har spørgsmål om mobile funktioner eller KYC. Husk at læse de fulde bonusbetingelser og udbetalingsregler før du kræver bonusser – især regler om omsætningskrav og maksimumudbetalinger fra free spins. Mobilspillere i Danmark får med Rabbitreel en moderne og sikker løsning til spil på farten. Tjek altid vilkår og kontakt support hvis noget er uklart.

Spillutvalg og spilleautomater hos Rabbitreel

Rabbitreel tilbyr et bredt og moderne spillbibliotek spesielt tilpasset norske spillere – med fokus på et stort antall spilleautomater fra kjente leverandører og nykommere i markedet. Plattformen aksepterer NOK og er bygget for å vise populære kategorier som megaways, jackpot-spill, nyheter og klassiske slots. For de som jakter variasjon og spesialfunksjoner finnes titler som Big Bass Splash, Rise of Olympus Extreme og Big Bass Reel Repeat, og et mangfold av studioer sikrer at det alltid finnes noe nytt å prøve. Hvis du vil utforske hele utvalget direkte og finne de beste kampanjene rundt free spins og multiplikatorer, se gjerne etter tilbud knyttet til spilleautomater hos Rabbitreel som ofte kombinerer velkomstbonuser og gratisspinn på utvalgte titler.

| Kategori | Eksempelspill | Leverandører |

|---|---|---|

| Megaways | Bonanza Megaways | Big Time / Red Tiger |

| Jackpot | Jackpot Frenzy | Netent / Microgaming |

| Nyheter og populære | Sugar Rush / Fire in the Hole | Pragmatic Play / Play’n GO |

Spillopplevelsen hos Rabbitreel er optimalisert for mobil – siden siden er responsiv fungerer de fleste spilleautomater sømløst på både iOS og Android uten egen app. Selv om grensesnittet i utgangspunktet er på engelsk, vil norske spillere likevel sette pris på rask navigasjon, filtrering etter leverandør og muligheten til å teste demomodus på mange titler før ekte penger settes inn. Rabbitreel samarbeider med et stort antall studioer for å sikre at både klassiske og eksperimentelle mekanikker er tilgjengelige.

- Stort utvalg av spilleautomater fra mange leverandører

- Spesialkampanjer og free spins knyttet til utvalgte titler

- Mobilvennlig og responsivt grensesnitt

- Filtrering etter kategori, popularitet og nyheter

- Tilgjengelighet av norske kroner – enklere innskudd og uttak

- Rask kundestøtte ved behov, samt ansvarlige spilleverktøy

For norske spillere som prioriterer variasjon og rettferdighet er det også positivt at Rabbitreel opereres under MGA-lisens, noe som innebærer regulering og krav til sikkerhet og rettferdig spill. Velg alltid spill med fornuft og benytt ansvarlig spill-funksjonene som innskuddsgrenser og selvstengelse om nødvendig. Utforsk spillene, prøv demoer, og sammenlign temaer og volatilitet før du satser de større beløpene – på den måten får du mest ut av Rabbitreel sitt varierte tilbud uten å ta unødvendig risiko.

HIGH REABILITY STANDARD

Making sure the high standard for reliability and performance efficiency for heat press machine.

BIGGER THE BETTER PERFORMANCE

Imported from the smallest to biggest digital heat press transfer technology equipment and machine.

Our Services

Distributor

We are the largest distributor for machine with licensed award for print and garment.

Garment Printing

Providing shirt printing with high quality materials including the best choice of garment.

DTF Material supplies

Providing printing material including dtf vinyl, ink, parts and many more.

Largest Distributor

Asia Apparel is a distributor, importer, exporter and leader of proven and reliable t-shirt printing, digital heat press transfer technology equipment, machines & supplies located in Singapore, (HQ) Malaysia, Thailand, other countries.

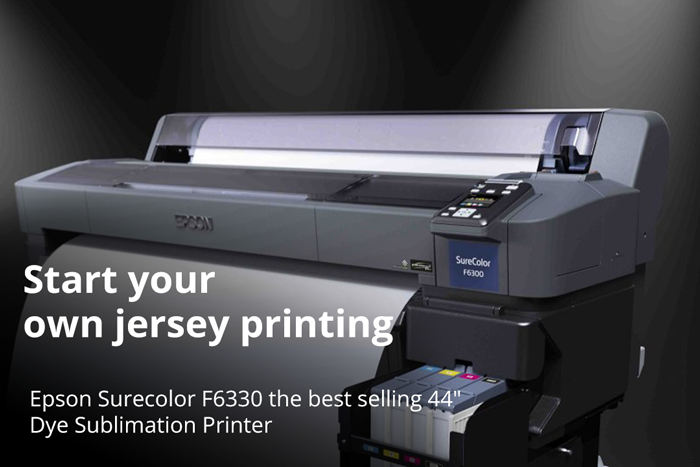

Authorise Dealer

One stop center for newly startup or current t-shirts printing and factories & businesses. We are authorise dealer for all of many well known brand. Among of that is EPSON.

PRINTING SERVICES

Quote the price for your garments

AS LOW AS 3%

Leasing Plan Now Available